Clearance

|

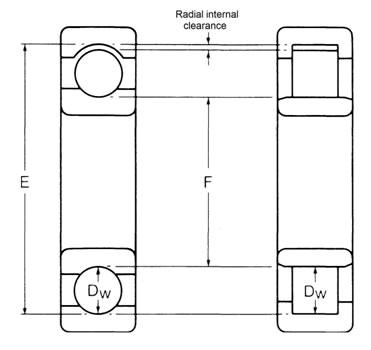

Bearing radial internal clearance relates to the total clearance between the raceways and rolling elements measured normal to the bearing axis.

|

|

In single row radial ball and cylindrical roller bearings this may be simply defined as being equal to the difference between the mean outer raceway diameter (E) and the sum of the mean inner raceway diameter (F) and twice the mean diameter of the rolling elements (2 Dw).

i.e. Radial internal clearance == E - (F + 2 Dw) This feature is not easily checked in assembled bearings, particularly ball bearings where the rolling elements should be central to the raceways. Allowance must also be made for the elastic deformation of rolling elements and raceways under gauging load.

|

|

Bearings are made to four standard groups of internal clearance

|

|

C2 smallest clearance - please check availability

CN normal clearance C3 larger clearance than normal C4 larger clearance than C3 - please check availability (C5 larger clearance than C4 - please check availability) |

|

Standard bearings are supplied normal clearance (CN) unless ordered differently. Normal clearance bearings are not marked with the internal clearance code. Radial ball bearings and spherical roller bearings have some axial clearance and this depends on rolling element size, raceway curvature, and radial internal clearance.

Values of radial internal clearance for the various bearing types are given in the following tables. Radial clearance is decisive for safe operation of a radial bearing. An installed bearing always has lesser clearance than it did before installation. In the course of operation there is a further change in radial clearance, mostly its reduction. The operating temperature gradient between the inner ring and usually better cooled outer ring. The radial clearance change is influenced further by elastic deformations being the consequence of load and outer heat sources. Cylindrical, tapered and spherical roller bearings are of higher rigidity and therefore should have lesser operation clearance needed for safe and reliable operation, especially under hard operation conditions. The radial clearance given by raceways dimensions, are manufactured with standard radial clearance slightly higher than the bearing operational clearance. Bearings of standard design have radial clearance adjusted so that one of the rings can be mounted fixed. This is acceptable for most of operation conditions. |